ptdome has been designed to be rapidly assembled and installed in 5 days or less, depending on size, location and availability of labour resources.

ptdome is assembled almost entirely at ground level. The 5m long main members, which make up about 90% of the structure, are easily placed in position before being bolted together on temporary scaffolds. This methodology heralds a new era in OH+S practices on a construction site as the risk of workplace injury is greatly reduced.

High tensile stressing strand is fed through the hollow sections of the side truss bottom chords and then stressed to precise loads by hydraulic jacks. This process 'lifts' the ptdome into its shallow dome shape as well as storing energy in the structure.

The post-tensioning process is undertaken by appropriately qualified stressing contractors under strict instruction and supervision by the s² company pty ltd.

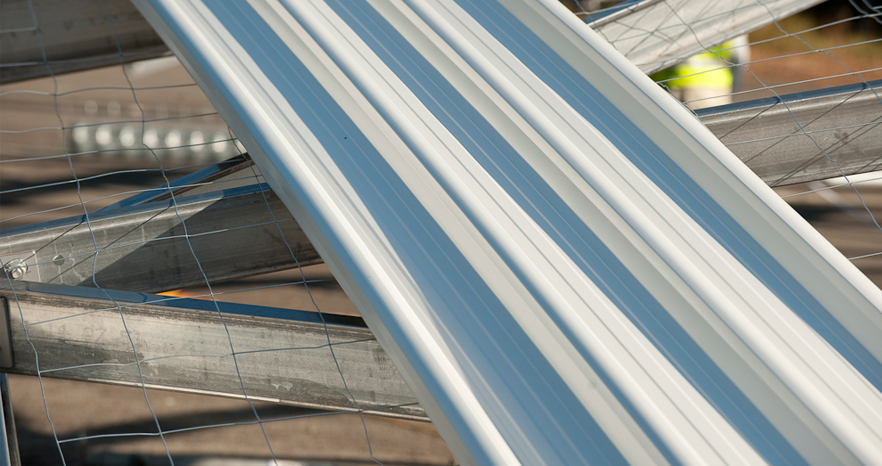

Steel sheeting or PVC fabric is installed while the ptdome roof structure is at ground level, without the need for lifting equipment of any kind. Use of a safety rail around the ptdome perimeter ensures that no harnesses are required on the roof as the risk of falling has been eliminated.

Lifting the ptdome roof element onto its four columns without cranes is achieved via a purpose designed lifting tripod and chain block system. Once lifted and the columns are in correct alignment, holding down bolts are secured to complete the ptdome installation.

The 'craneless lift' takes less than 2 hours to complete, and can be used on ptdome modules up to 35m x 35m.

![[image]](/media/15105/im1.jpg)

![[image]](/media/15110/im2.jpg)

![[image]](/media/15115/im3.jpg)

![[image]](/media/15130/im6.jpg)

![[image]](/media/15120/im4.jpg)

![[image]](/media/15125/im5.jpg)

![[image]](/media/15135/im7.jpg)

![[image]](/media/15140/im8.jpg)